750V DC SWITCHGEAR REPLACEMENT – CUSTOM HOUSE

DLR

Enable Infrastructure has been working with DLR (Docklands Light Railway) for the design, supply, and installation of replacement of 750V DC Switchgear type HSNP at Custom House Substation (CHS) with modern equivalent. The work is part of the TfL & DLR ongoing works. With the objectives of the project are to maintain the existing level of train service, to minimise the risk of disruption to customers and increase efficiency and safety for operations of maintenance.

The project

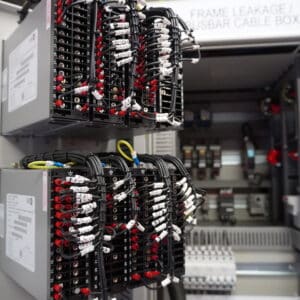

The switchgear being upgraded includes a 6-panel switchboard, a 110V battery charger, and a frame leakage/busbar cable box. These components are crucial for the proper functioning of the substation and ensuring the reliable supply of power to the trains. By upgrading the switchgear, Enable Infrastructure and DLR are ensuring that the infrastructure is up to date and meets the necessary safety standards.

The challenge

- Minimising Disruption

- Ensuring the replacement of the switchgear did not significantly disrupt train services required careful planning and coordination to maintain operational continuity.

- Safety

- Maintaining safety during the replacement process was crucial. This involved implementing stringent safety protocols and ensuring that all work was carried out in a controlled and secure environment.

- Complexity of Installation

- The design, supply, and installation of new switchgear involved complex technical requirements. This necessitated precise engineering and execution to ensure compatibility and functionality.

- Enabling Works and Commissioning Access

- Facilitating the project required enabling works and commissioning access, which involved additional logistical and operational challenges

The solution

- The original agreed construction programme duration for the project was 9 weeks, but through working efficiently and competently, the site team were able to reduce this programme to 7 weeks which was well-received by both the client and maintainer.

- Prior to the works taking place, Custom House substation was put into bypass by the network maintainer, KAD, with the assistance of Enable – disconnecting the track feeders during a possession – and put on a trial period for a week. Once passed, the worksite was handed over to Enable and the team began on decommissioning the redundant switchgear.

- After the switchgear was removed, civil works extended the trenches for cabling. Once completed, the switchgear was delivered and moved into position. Commissioning took place over 3 shifts with Enable, KAD, and Sella Controls present. The first shift focused on reconnecting cables, SCADA update, and terminations. During the 2nd shift, both Rectifiers 1 and 2 were commissioned. The 3rd shift reconnected track-feeder cables, commissioned the SCADA, and put the new switchgear into service. Testing documentation was completed by Enable’s Testing & Commissioning engineer.

- Following energisation of the switchgear into service, all cable penetration entry points were fire-stopped by our approved fire-stopping contractor and the DC Switch room floor was painted prior to walk-out with client to inspect installation.

The deliverables

- Replacement of the HSNP switchgear at Beckton substation and Custom House Substation with modern equivalent.

- Provision of switchgear with DC protection system compliant with ES-606.

- Commissioning of the new switchgear and wiring interfaces with operational plant to be retained, such as Telecode 80, SCADA, 11kV switchgear and emergency stop push buttons.

- Replication of existing SCADA Inputs/Outputs (I/Os) and installation of additional (I/Os) for extended functionality of equipment.

- Civil modifications if required to allow the new DC plant to be installed.

- Mechanical modifications in the cable route systems within and outside of the DC rooms.

- Replace all cabling and small wiring to Switchgear.

- Review and upgrade of the 110V DC battery chargers. Modification or provision of new battery chargers if required.

- Provision of circuit and busbar earthing facility via earthing trucks.

- Provision of castell key interlocking and modifications required to achieve full interlocking when carrying out transformer rectifier set isolations.

Gallery

Your Trusted Partner for Infrastructure Excellence

Whether you’re upgrading critical rail networks, improving highways, delivering essential utilities, or developing energy connections and power systems, Enable Infrastructure is your trusted partner for success.

Join us in our mission to deliver innovative, on-time, and on-budget infrastructure solutions that shape the future. Together, we push boundaries and deliver outstanding results across rail, energy, utilities, and highways sectors.

Discover how our award-winning expertise can help you navigate complex projects with confidence.

Get in touch